Lean Six Sigma™

Nowadays business environment has reached a point where competition for survival and market share growth are essential. Each organization must strive for excellence in order to remain on the market and more than ever it is necessary to implement quality management systems within organization in order to achieve this goal.

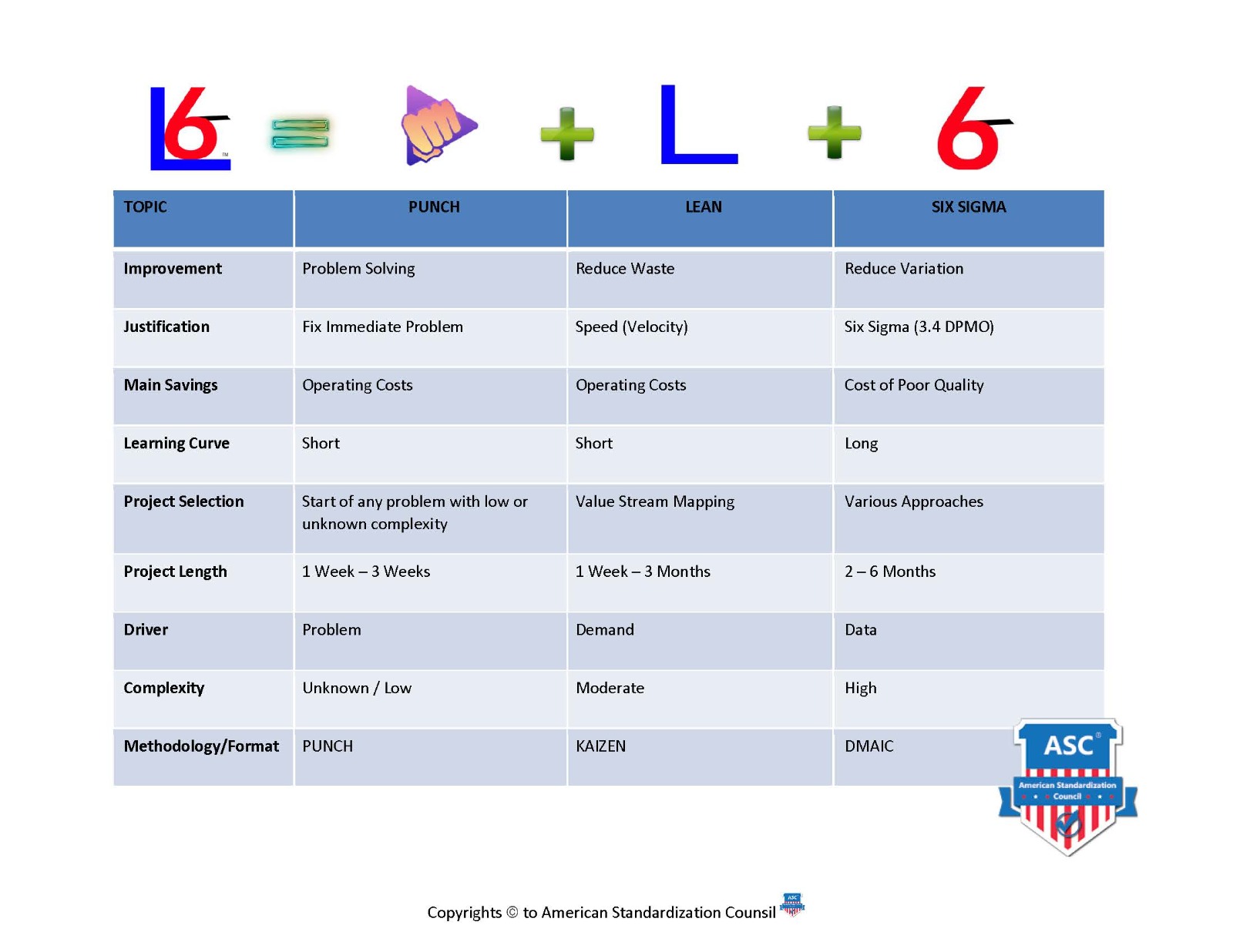

Lean Six Sigma™ is the tool for process improvement used by organizations to reduce costs and improve quality of products.

Speaking about Lean and Six Sigma application to improve processes, lean approach offers a set of solutions to muda in a high-variety production environment.

Six sigma applies to the problems addressed by lean but also seeks to solve other problems common to production.

However, because both six sigma and lean address the problem of muda, and there is difference in the complexity levels required to start either project so PUNCH™ is used as a triage step, to define the complexity, resolve low Complexity problem or transfer the project to one of the other two or both, where there is a great deal of overlap.

Approaches are complements to one another. Most companies using the integrated approach began by applying the basic PUNCH and lean production tools and techniques such as basic housekeeping using 5S practice, standardized work, total productive maintenance, etc.

Once lean tools and techniques eliminate much of the noise from a process, Six Sigma then offers powerful solutions to chronic problems.

Based on the synergism between Lean and Six Sigma methodologies, Lean Six Sigma™ was developed as a powerful quality management tool, where Lean Six Sigma™ fundamentals can be summarized in four keys: delight customers–delivering higher quality service in less time, improve processes – eliminate defects and focus on how the work flowed through the process, work in teamwork, sharing ideas with each other so they could solve the problem and base decisions on data and facts.

ASC Lean Six Sigma™ Accreditation Programs:

- For Companies:

- Lean Six Sigma™ DOJO: accreditation for companies providing Lean Six Sigma™ Training.

- Lean Six Sigma™ SENJO: accreditation for companies applying Lean Six Sigma™ in their Quality management System

- For Personnel

- Lean Six Sigma™ Yellow Belt

- Lean Six Sigma™ Green Belt

- Lean Six Sigma™ Black Belt

- Lean Six Sigma™ Master Black Belt

- Lean Six Sigma™ Grand Master

- Lean Six Sigma™ Champion

- Lean Six Sigma™ for executives

- CEO of Lean Six Sigma™